To provide faster and more efficient service, NTS manages in-house electronic board assembly, electromechanical integration of equipment and systems, wiring and testing. SMT, THT and test assembly lines enable partner companies to have the latest and most efficient technology to grow and develop their products, all updated to operate according to RoHS regulations and standards.

Management in its entirety of the supply chain, from the purchase of electronic and mechanical components to after-sales service, are a guarantee of added value in NTS’ customer projects.

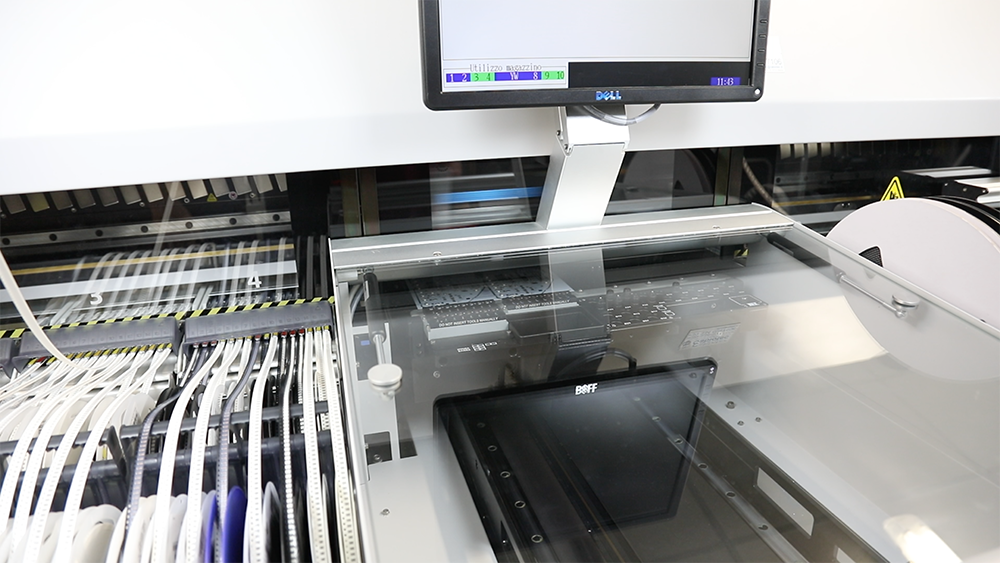

EMS Assembly Line

- SMT Assembly Lines

NTS’ goal of providing its customers with the highest quality standards in SMD assembly results in the use of the highest technology to solder every type of component, even the most complex, such as BGA, QFP, QFN, POP, etc.

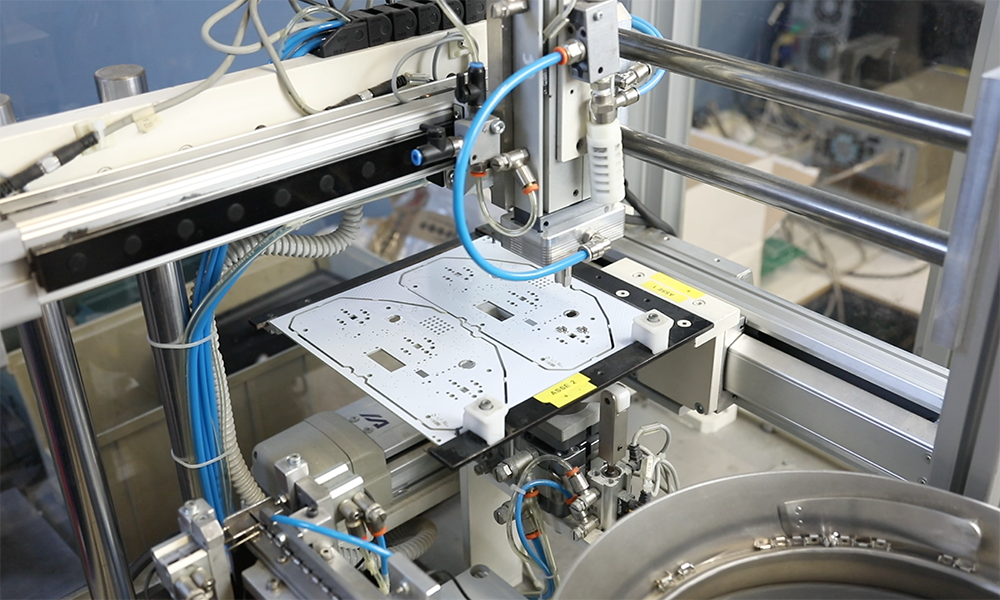

For solder paste deposition of PCBs, two state-of-the-art screen printing machines are in operation, including SJ Innotech HP-520S, equipped with 2D control for solder paste deposition verification

PTH assembly lines and selective soldering machine

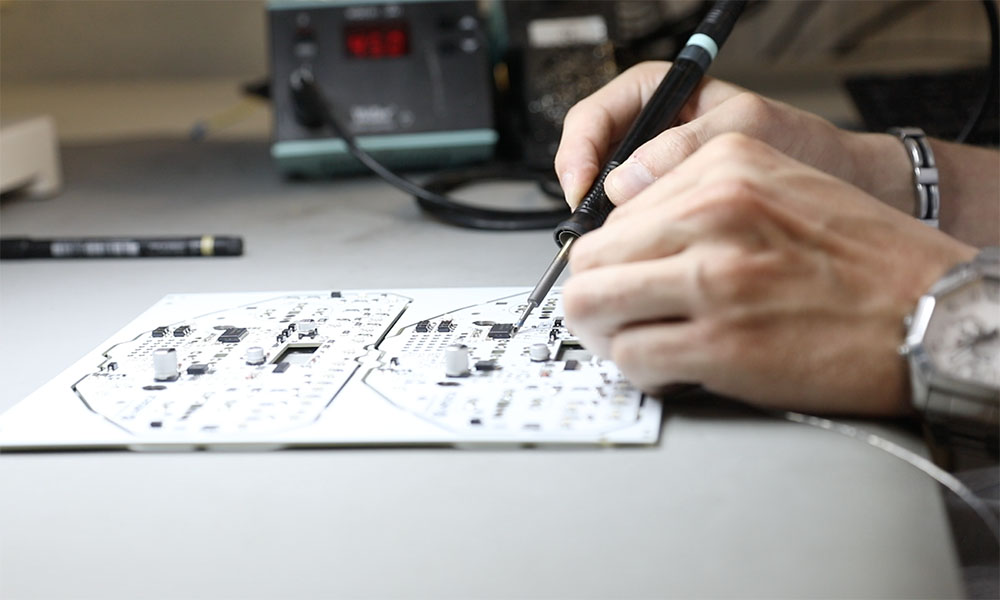

NTS offers manual soldering service carried out on ESD benches by experienced and highly qualified personnel according to current regulations.

This activity, which can be carried out in both lead free and lead tin technology, is supported by double wave soldering machine and selective soldering machine.Each selective soldering procedure is unique and requires its own specific management, including the choice of the appropriate dedicated tools, so it is necessary to have an overview of the process and the product to be worked on.

Assembly Supplementary Services

Test

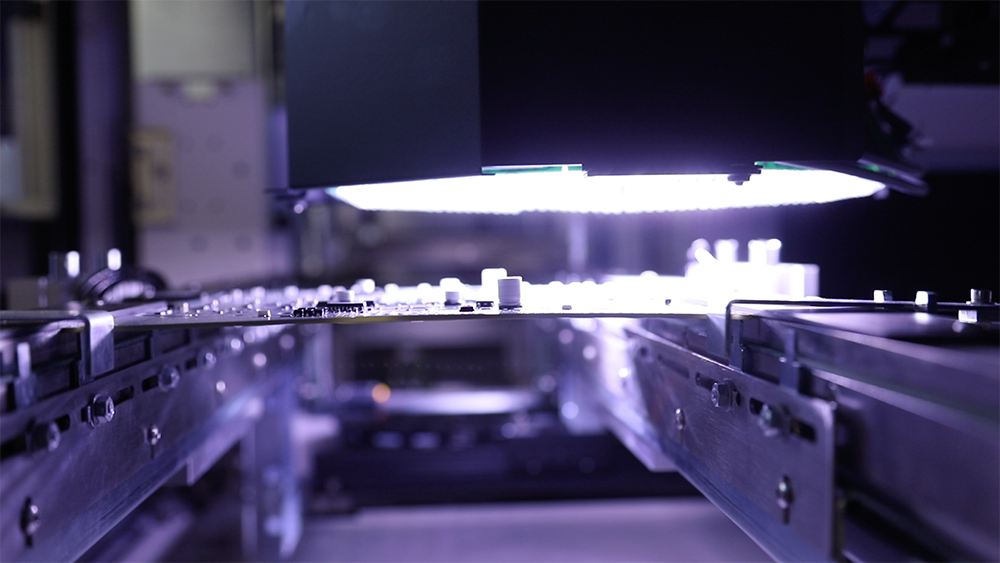

AOI –

Through the use of the Nordson FX-940 AOI machine, we offer the ability to achieve high automatic inspection performance, speed, result quality, and the greatest analysis coverage.

The machines can be configured with one vertical camera, one vertical camera accompanied by 4 other angular cameras, all with high definition to allow operators the highest levels of performance.

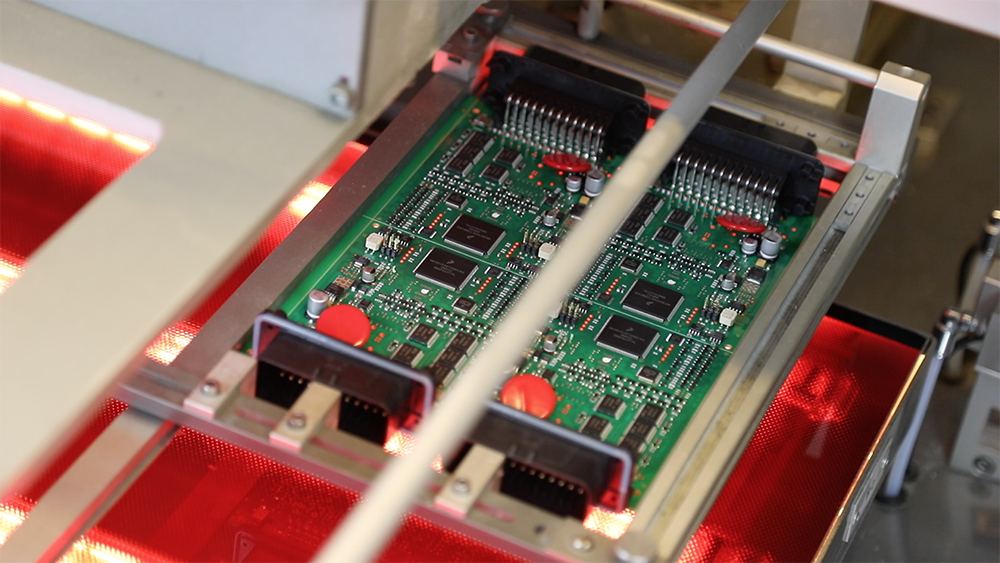

X-Ray –

To complete the inspection range, NTS has implemented its line with a Nordson Jade FP XD7500VR X-Ray machine that allows fast inspection with different resolutions with automatic handling, analysis in space thanks to multiple detectors to ensure quality and stability of analysis and the of defect control in the top and bottom sides of the board with a single scan.Functional –

Depending on the needs of its customers, NTS performs functional testing to specifications provided but also offers the design and manufacture of equipment to perform such testing.

- Burn-in (Thermal Cycle).

Thermal cycling involves bringing the board to high positive and negative temperatures and is aimed at the onset of all component issues as well as possible assembly defects. The test is done by running the board at a temperature slightly lower than the maximum stated in the specifications.

Conformal Coating

Upon customer specification, at NTS it is possible to coat the boards in order to provide protection against various environmental factors that may adversely affect the functionality of the boards and increase their electrical insulation.

Depending on the product used, coolers are active aimed at conserving humidity and temperature of the resin (Auto Dry Cabinet DRT254C).

FAI (First Article Inspection)

In order to provide objective evidence on a first article produced that all engineering specifications, drawings, and any other specifications that may be required have been properly complied with, verified, and implemented, at the customer’s request NTS performs the First Article Inspection report on both productions and prototypes.

Distribution and Logistics

The old concept of “logistics,” understood as a set of procedures for moving materials and products, is being superseded by the new perspectives offered by NTS in terms of shipment customization and flexibility of the entire procedure, increasingly an incident factor for many customers.

After-Sales Service and Warranty Repairs

To complement the all-around service, NTS offers after-sales support for warranty and non-warranty repairs through careful failure analysis and proposing solutions that are as effective and quick as possible.

Field Technical Service

NTS offers field service and maintenance of installed equipment, both nationally and internationally, guaranteeing the highest quality standards and prompt service for each scenario, with highly qualified and certified personnel.